A young researcher in chemical and biomolecular engineering (ChBE) at Rice, Haotian Wang, has been awarded a four-year, $2-million collaborative grant by the Emerging Frontiers in Research and Innovation program of the National Science Foundation to explore ways to directly convert waste carbon dioxide (CO2), the bane of Earth’s atmosphere, into pure liquid fuels.

The assistant professor and William Marsh Rice Trustee Chair of ChBE proposes development of an electrochemical modular system that will provide, “a sustainable, negative-carbon, low-waste, and point-source manufacturing path preferable to traditional large-scale chemical process plants.”

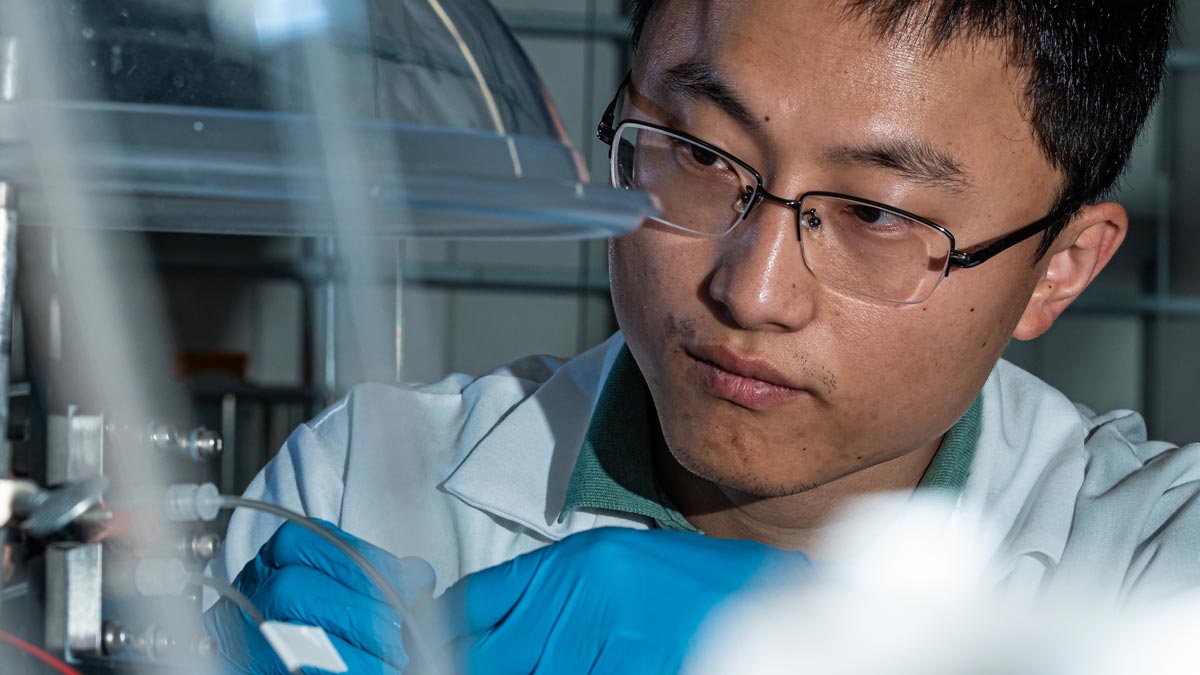

Since joining the Rice faculty in 2019, Wang has developed a catalytic reactor that uses CO2 as its feedstock. The NSF grant would address some remaining challenges to be overcome before the renewable strategy could be applied practically on a commercial scale.

Until now, the generated liquid products from electrochemical CO2 reduction-reaction systems have been mixed with liquid electrolytes/soluble solutes, which requires energy- and cost-intensive separation processes to recover pure liquid fuel solutions. In addition, efficient electrochemical CO2 reduction-reaction catalysts for target products are scarce. There is still a lack of new redox-active CO2 carriers for effective electrochemical CO2 capture from point sources such as flue gas.

“To address these challenges, our project is interdisciplinary. We include experts in catalysts and electrolyzer design, polymer engineering, density functional theory simulations and CO2 capture,” Wang said.

Wang’s co-principal investigators are Rafael Verduzco, professor of ChBE at Rice; T. Alan Hatton, the Ralph Landau Professor and Director of the David H. Koch School of Chemical Engineering Practice at MIT; and Yuanyue Liu, assistant professor of mechanical engineering at the University of Texas at Austin.

“We intend to build an electrochemical modular system as a platform for a continuous conversion process of simulated flue gas to pure liquid fuels. We address both materials-level design and device-level engineering,” Wang said.

Experiments and simulations will be integrated in each of the project’s components, creating what Wang calls “a systematic feedback loop to accelerate design and understanding of CO2 capture and conversion systems tailored for small-scale distributed chemical manufacturing.”

“We will work closely with Prof. Wang and other collaborators,” Verduzco said, “develop new polymer electrolytes, design more effective catalysts, improve CO2 adsorbents and optimize the overall device for continuous generation of pure liquid fuels from CO2.”

Earlier this year, Wang received a three-year, $240,000 research grant from the Houston-based Robert A. Welch Foundation for related research.

“Converting waste CO2 into valuable chemicals and fuels,” Wang said, “using renewable electricity can distribute the way we produce chemical feedstocks, while making significant contributions to establish a potential anthropogenic carbon loop in the future.”